FREE QUOTE CALL OR TEXT

0424 408 330

No Call Out Fee Conditions apply*

GET YOUR JOB BOOKED IN AND FINISHED TODAY !!

Concrete Cancer Repairs Service

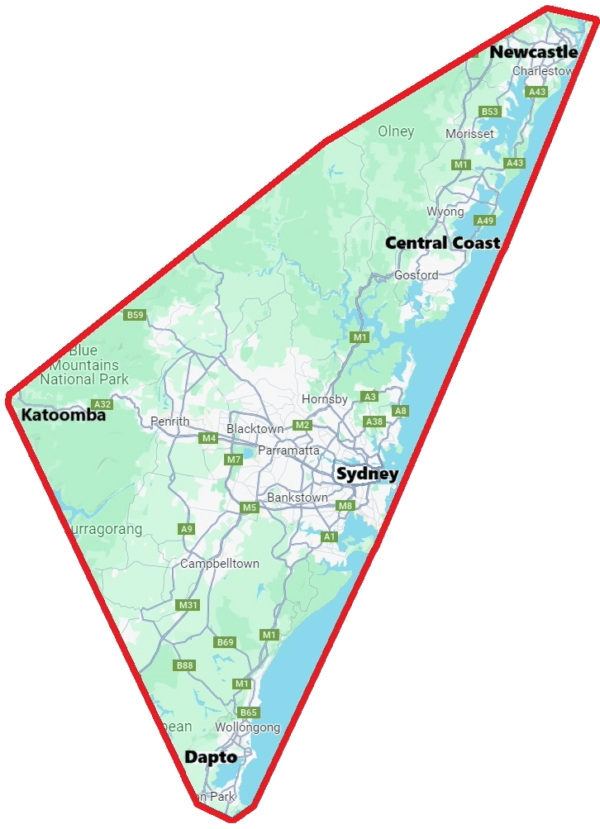

Carpet Removal Sydney’s team is your trusted specialist in concrete cancer repairs. Our team provides Free Site Inspections and Quotes for concrete cancer repairs and concrete spalling repairs throughout Sydney. Our skilled team is committed to restoring the strength, safety, and appearance of your concrete structures, delivering durable, high-quality results you can rely on.

Our concrete cancer repair process is designed to permanently address reinforcement corrosion and restore structural integrity. Each stage is carried out using industry-approved methods and materials to ensure durability, safety, and long-term performance.

FREE QUOTE CALL OR TEXT 0424 408 330

Trusted by Builders, Strata Managers & Property Owners

GET YOUR JOB BOOKED IN AND FINISHED TODAY !!

Expert Concrete Cancer Repair Service In Sydney

Expert Concrete Cancer Repair Service In Sydney

Our Concrete Cancer Repair Process

Our concrete cancer repair process is designed to permanently halt reinforcement corrosion and restore the structural integrity of affected concrete elements using industry-approved remediation methods.

Step 1: Free Site Inspection And Quote

We begin with a comprehensive on-site assessment and inspection to evaluate the extent of concrete damage, identify the cause of reinforcement corrosion, and determine the most appropriate repair approach. Based on this assessment, we provide a clear, obligation-free quote outlining the required works.

Step 2: Section Preparation

Damaged concrete areas are carefully cut and edged to create a clean surface for restoration.

Step 3: Dust-Free Concrete Removal

Specialised dust-reducing jackhammers are used to safely remove all weakened and loose concrete around the corroded steel.

Step 4: Rust Treatment

Exposed steel is treated using wire brushes or grinders to remove rust and prepare it for protective coatings.

Step 5: Cleaning Surfaces

All concrete and steel surfaces are meticulously cleaned to ensure primers and protective treatments adhere properly.

Step 6: Primer and Corrosion Protection

We apply high-grade epoxy primers and rust inhibitors, followed by a protective barrier to reduce the risk of future corrosion.

Step 7: Reinforcement Repair or Replacement

Where necessary, steel reinforcement bars are replaced or supplemented to restore structural integrity.

Step 8: Protective Coatings & Waterproofing

Protective coatings and waterproofing systems are applied to the repaired area where required to reduce moisture ingress and help prevent future corrosion.

Step 9: Concrete Restoration

New concrete is carefully applied at the correct thickness and allowed to cure, fully restoring the surface and strength of the structure.

Common Signs Of Concrete Cancer

Concrete cancer often develops internally before visible damage becomes severe. The following warning signs indicate corrosion of reinforcement steel and underlying concrete deterioration.

Rust Streaks & Discolouration:

Brown or reddish staining on concrete surfaces often signals corrosion occurring within embedded steel reinforcement.

Cracking in Concrete:

Hairline cracks or wider fissures may indicate internal expansion of rusting steel, which worsens over time if untreated.

Spalling, Flaking, or Crumbling Concrete:

Sections of concrete breaking away from the surface are a strong indicator of advanced concrete cancer.

Hollow or Drummy Areas:

Concrete that sounds hollow when tapped suggests delamination caused by corrosion beneath the surface.

Water Ingress, Damp Patches, or Pooling:

Persistent moisture accelerates corrosion and significantly increases deterioration risk.

Bubbling or Flaking Paint & Coatings:

Peeling finishes on balconies, soffits, or ceilings can reveal underlying concrete damage.

Faulty Expansion Joints:

Failed joints allow excessive movement and moisture penetration, contributing to cracking and spalling.

Thin Concrete Cover:

Reinforcement positioned too close to the surface is more vulnerable to corrosion.

Corroded Embedded Fixtures:

Rusting bolts, anchors, or fixings can initiate concrete degradation in surrounding areas.

Exposed Reinforcement Steel:

Visible steel indicates advanced concrete cancer requiring immediate professional repair.

When Professional Repairs Are Required

If one or more of these signs are present, early assessment and professional concrete cancer repairs can prevent extensive structural damage and reduce long-term repair costs.

What Is Concrete Cancer & Why It Matters

Concrete cancer, also known as concrete spalling, occurs when steel reinforcement within concrete begins to corrode. As the steel rusts, it expands, placing internal pressure on the surrounding concrete. This expansion causes cracking, delamination, and eventually the breaking away of concrete from the surface.

Concrete cancer most commonly affects balconies, slabs, columns, beams, car parks, and exposed structural elements—particularly in coastal and high-moisture environments such as Sydney and NSW.

Why Concrete Cancer Occurs

Concrete cancer develops when moisture, oxygen, and salts penetrate the concrete and reach the reinforcing steel. Common contributing factors include:

– Water ingress through cracks or failed waterproofing

– Carbonation of concrete over time

– Chloride exposure from coastal air or de-icing salts

– Poor original concrete coverage over reinforcement

– Age-related deterioration of the slab

Once corrosion begins, the damage progresses internally—even if surface cracking appears minor.

The Importance Of Proper Repairs

Effective concrete cancer repairs require more than surface patching. Damaged concrete must be fully removed, reinforcement steel treated and protected, and repairs reinstated using compatible materials. Correct remediation halts corrosion, restores structural performance, and extends the service life of the structure.

Concrete Cancer Repairs Results – Before & After

This before-and-after concrete cancer repair example shows deteriorated concrete professionally repaired through the removal of damaged material and treatment of affected reinforcement. The concrete is structurally reinstated to a sound, durable condition, ready for protective coatings, waterproofing and final finishes—demonstrating the effectiveness of professional concrete cancer repairs in restoring structural integrity and long-term performance.

Key Factors That Increase The Risk Of Concrete Cancer

Several conditions can make concrete more susceptible to damage and reinforcement corrosion:

Magnesite Flooring:

Properties built from the 1920s through the 1990s often contain magnesite flooring. While it was a common choice at the time, this material can trap moisture and contribute to internal steel corrosion. Professional removal is recommended to avoid long-term structural issues.

Coastal Locations:

Buildings near the ocean face harsh conditions due to salt-laden air. Salt can penetrate concrete and accelerate the rusting of the steel reinforcement inside.

Water Penetration:

Cracks, unsealed joints, or gaps in the concrete allow water to reach the steel beneath. Concrete’s natural pores can also let moisture and contaminants travel, gradually corroding the reinforcement.

Salt Exposure:

Salt from coastal environments can speed up the corrosion of internal steel, weakening the overall structural strength of the concrete.

Carbonation:

Over time, concrete reacts with carbon dioxide in the air, lowering its alkalinity. This diminishes its natural ability to protect embedded steel from rust.

Age and Environmental Wear:

Older structures often experience concrete breakdown due to prolonged exposure to weather, moisture, and pollutants, leaving steel more vulnerable.

Insufficient Concrete Cover:

When the concrete layer over the steel is too thin, the rebar is more exposed to moisture and corrosive agents, increasing the likelihood of deterioration.

Substandard Construction:

Poor-quality concrete, improperly placed steel, or uncleaned reinforcement before pouring can all trigger early signs of concrete damage.

Ineffective Waterproofing:

Deteriorated waterproofing membranes or inadequate drainage allow water to infiltrate, accelerating internal corrosion.

Structural Stress and Cracks:

Foundation movement, heavy loads, or normal settling can cause small fractures. These cracks act as direct channels for water to reach the steel.

Mixed Metals:

Using different types of metals together in the concrete can trigger electrochemical reactions, speeding up the corrosion of steel components.

Why Choose Us For Concrete Cancer Repairs

We specialise in professional concrete cancer repairs across Sydney, delivering long-term structural solutions—not cosmetic patch-ups. Every project is assessed, prepared, and repaired using industry-approved methods to ensure durability, compliance, and safety.

What Sets Us Apart

Specialist Concrete Repair Expertise:

We focus on concrete cancer remediation, spalling repairs, and structural concrete restoration.

Correct Repair Methods:

All damaged concrete is removed, reinforcement steel is treated, and repairs are reinstated using compatible repair mortars.

Licensed, Insured & Experienced:

Our team operates to Australian Standards with full insurance for peace of mind.

Durability-Focused Repairs:

Repairs are designed to prevent recurrence, not just cover visible damage.

Residential & Commercial Capability:

From private balconies to large strata buildings, no shortcuts, no fillers.

Clear Quotes & Honest Advice:

Transparent pricing with no hidden repair surprises.

FREE QUOTE CALL OR TEXT

0424 408 330

No Call Out Fee Conditions apply*

GET YOUR JOB BOOKED IN AND FINISHED TODAY !!